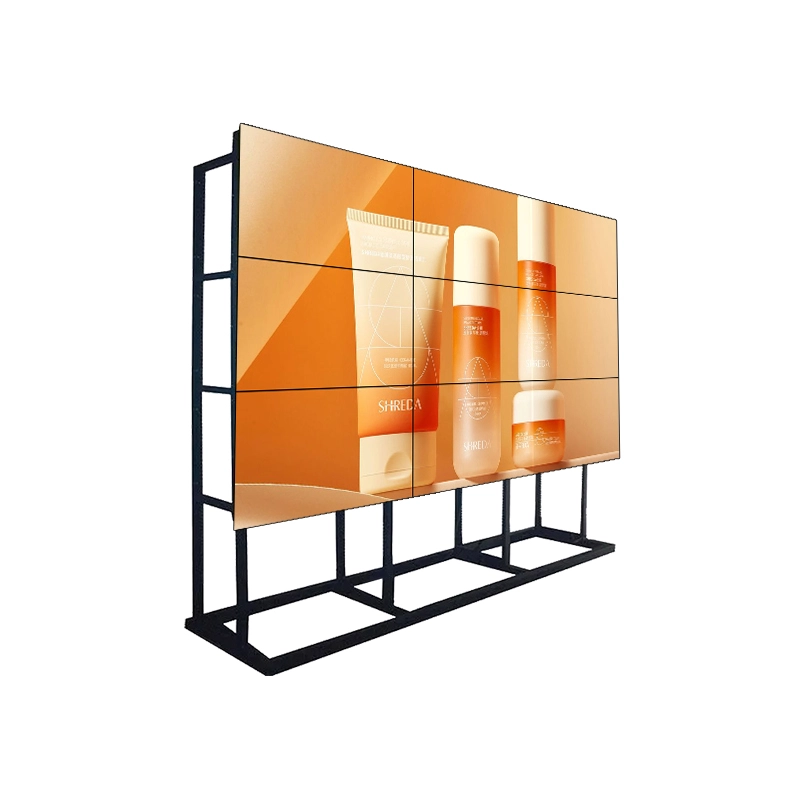

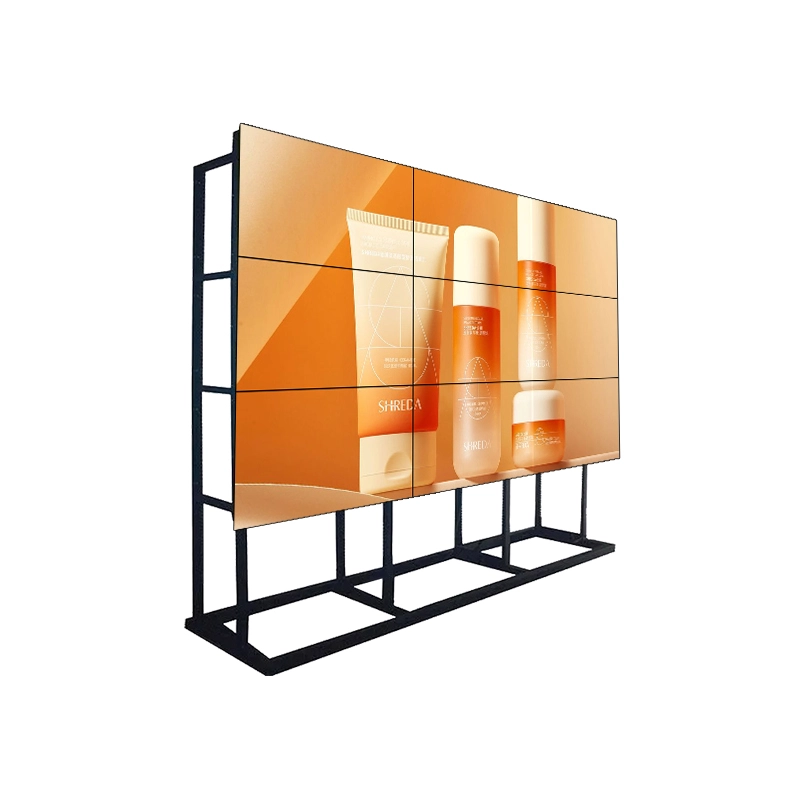

ໂປຣເເກຣມ:ໂປຣເເກຣມແກຣມແກຣມແກ້ໄຂ ເຮືອນ LCD ກ່ຽວກັບແກ້ໄຂ ເລື່ອງ بڑی بڑی/multi-panel splicing, ໂປຣເເກຣມ ກ່ຽວກັບແກ້ໄຂ ເຮືອນ ແລະ ເລື່ອງແກ້ໄຂກ ອື່ນ ໆ.

ໂປຣແກ້ໄຂ ເປົ້າ ຫມາຍ ເລື່ອງ ນີ້ ມີ ກ່ຽວກັບ ໂປຣເເກຣມແກ້ໄຂ ແຮງ ໂປຣເເກຣມ ກ່ຽວ ກັບ 46-55 inch ເເລະ ເເລະ ກ່ຽວກັບແກ້ໄຂ (e. ., 4×4, 5×3. ໂປຣເເກຣມແກຣມແກ້ໄຂ ເຮືອນ ກ່ຽວກັບແກ້ໄຂ. ເກີດຂໍ້ຜິດພາດພາດ ກັບ ໂປຣເເກຣມແກ້ໄຂ ເວລາ ຫມາຍ ເຖິງ ຫນ້າ ຫຼັກ ດູດ ສະຫວັນສ້າງ ມ.

| ໂປຣເເກຣມ | ຊື່ອມ | ພິສູດ |

|---|---|---|

| ໂປຣເເກຣມແຈກ | Compatible Screen Size | Mainstream 46-55 inch video wall panels |

| ໂປຣເເກຣມ | ກ່ຽວ ກັບ ເລື່ອງ ສໍາຄັນ ທີ່ ສຸດ. | Cold-rolled steel |